Home / Plastic Engineering

Plastic Engineering

Plastics Engineering is the foundation that BTC Mold is built upon. We lead with engineering on all plastic injection molded projects and pride ourselves in assisting our customers to solve complex plastics design and engineering problems.

Product design

Established in 2001 with a focus on mold design and manufacturing, BTC Mold has since emerged as a leader in specialized tooling and advanced injection molding techniques. With nearly two decades of experience, we have honed our expertise in multi-shot injection. We excel in gas-assisted injection, thick wall molding, and automatic insert molding, positioning us as the preferred choice for a variety of molding needs.

While we take pride in our rich history, our primary focus today is centered on advanced injection molding solutions tailored to meet the needs of diverse industries. At BTC Mold, we provide a comprehensive, vertically integrated service. From the initial design phase to the delivery of the final product, we work hand-in-hand with our clients, ensuring precision and quality at every stage.

Entrust your projects to BTC Mold, and let our extensive experience propel your success.

Material Development

Our depth of experience has allowed us to work with the full range of commodity in simple products to applications in environments. We also collaborate regularly with the world’s leading plastic compounders on plastic material development for specific product applications.

These partnerships provide additional support from polymer engineering laboratories and plastic resin material development experience that we offer to our customers.

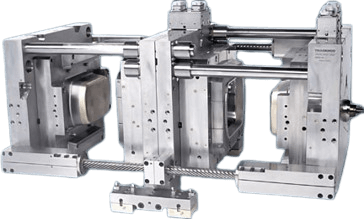

Tooling

As a custom manufacturer of plastic, BTC Mold manage the tool design and build of low volume simple geometry injection molded pats to fully automated, high volume injection molded finished with complex geometry and aggressive materials.

Production, Assembly and Automation

BTC Mold engineers consider the secondary operations and cycle time of the plastic molded part when designing the tool to build in manufacturing efficiencies at the molding press. For complex assemblies that require multiple components, our Industrial Systems Engineers lay out the assembly process, engineer and build custom fixtures and assembly processes to reduce cost and increase throughput.