Home / Capacity

Capacity

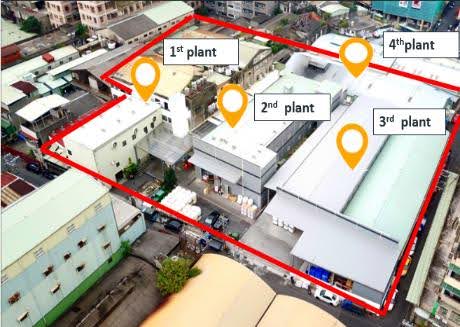

Taiwan Base

BTC Mold is located in the mechanical molds town in Taiwan,

Thousands of the related satellite factories nearby.

| Plant | Production area /m² | Storage area /m² | Plant area /m² | Height /m | Injection machines | Material |

|---|---|---|---|---|---|---|

| 1st Plant | 1,700 | 2,000 | 6,400 | 16 | 14 | PE/PP |

| 2nd Plant | 1,100 | 550 | 1,650 | 10 | 17 | HIPS/ABS |

| 3rd Plant | 580 | 580 | 1,160 | 5 | 14 | RPP/RPET |

| 4th Plant | 370 | 370 | 740 | 6 | 8 | RPP/RPET |

| Total | 3,750 | 3,500 | 9,950 | 53 |

Advanced Equipment

Injection Machine

| Double shot | Single shot | Total | Percentage | |

|---|---|---|---|---|

| High-Tonnage (550 to 1100 Ton) | 8 sets | 9 sets | 17 sets | 33% |

| Mid-Tonnage (250 to 450 Ton) | 18 sets | 5 sets | 23 sets | 44% |

| Low-Tonnage (110 to 250 Ton) | 9 sets | 4 sets | 13 sets | 23% |

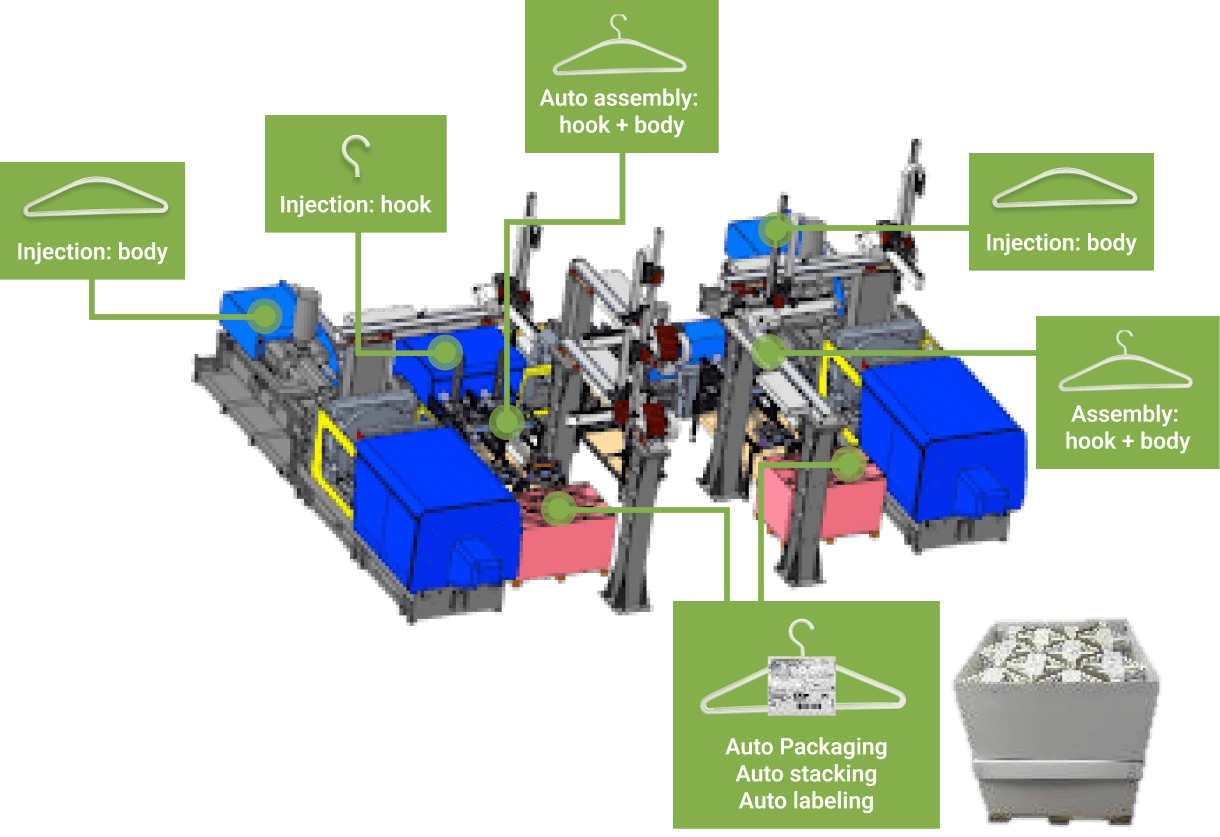

BTC Mold Capacity-High Automation

One Stop Integration

Vertical Integration

Mold Design

Mold Manufacture

Plastic injection

Assembly

Cost-Effectiveness

Reduce labor costs and waste

Efficiency

Lead to faster turn around times.

Innovation

Innovative manufacturing processes result in better performance and features.

Integration

Handle multiple production steps, make it in smooth and short production.

In-mold Assemblty

Automatic assembly

Automatic labeling

Automatic stacking

Automatic packaging

One Stop Integration-example: hanger

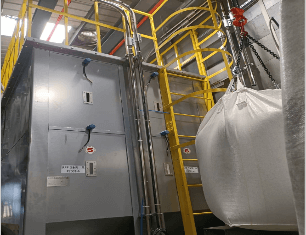

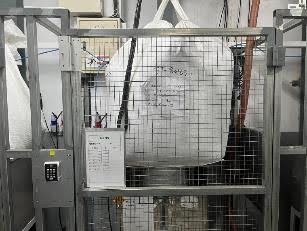

Central Feeding system

Intelligent

Control the feeding of one or many vacuum pumps and multiple injection molding machines. Low failure rate, and cost-saving.

Low Noise and Less Waste

Reduce the material waste and noise to ensure no material and dus contamination.

Flexible design

The design optimal solution can meet and optimize customers' production processes.

Centralized Management

Making a more spacious injection molding workshop and safer operating environment.